Through our PM-HIP technology, we are well suited to domestically manufacture components previously made by casting or forging, but at lower required volumes and higher part mix regardless of material or size of part.

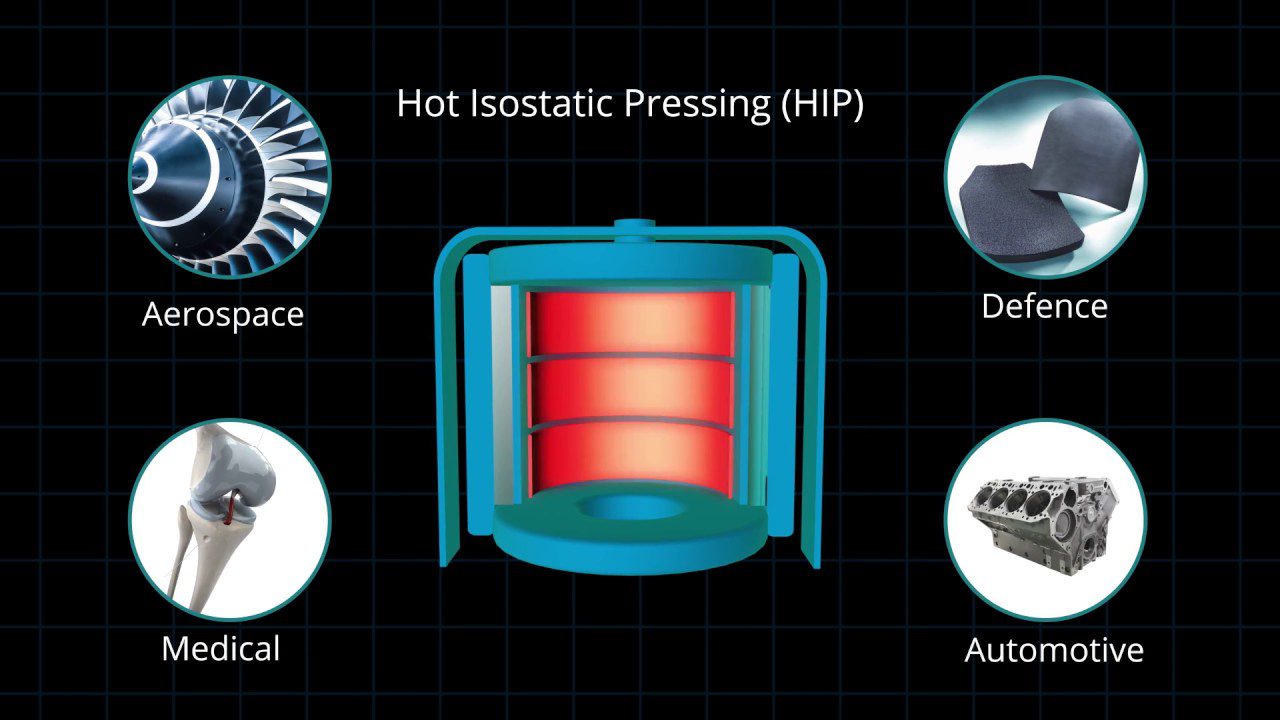

Powder Metallurgy – Hot Isostatic Pressing (PM-HIP):

Our approach to manufacturing is deeply collaborative, combining extensive knowledge in numerical modeling with the latest advancements in Powder Metallurgy – Hot Isostatic Pressing (PM-HIP). With a team of experts dedicated to ensuring precision at every stage.

Our near-net shape manufacturing process minimizes waste and reduces the need for extensive machining, saving time and resources without compromising on quality. This efficiency enables us to deliver components that meet exacting specifications and exceed industry standards.

At Amaero, we work closely with our clients to understand their specific needs and design solutions tailored to their applications. Our team’s expertise in advanced numerical modeling allows us to optimize every part for strength, weight, and durability, ensuring performance in the field.

Our advanced manufacturing process is powered by Hot Isostatic Pressing (HIP), an innovative technique that fully consolidates the metal powder producing isotropic forge-like material properties, ensuring the highest quality in every component we produce.

Defect-Free, High-Integrity Parts: The HIP process utilized eliminates internal defects and material porosity, resulting in components with superior strength, durability, and corrosion resistance. This method creates parts that are ideal for high-stress applications where reliability is critical.

Reduced Material Waste and Cost-Effectiveness: The near-net shape HIP process reduces excess material and machining requirements, making it a cost-effective solution for producing high-quality parts. This efficiency is especially valuable for industries that need to maintain strict budget constraints without compromising on performance.

Applications in Demanding Industries: Amaero’s PM-HIP technology is trusted across industries where high-performance materials are essential. From defense to aerospace and energy, our components provide the resilience and strength needed for extreme environments, making us a preferred partner for advanced manufacturing solutions.

Our dedication to excellence goes beyond the technical. Led by experts like Fred Yolton, our Technical Fellow in Powder Metallurgy & Materials Engineering, we believe in a culture of continuous improvement, knowledge sharing, and precision:

As a leader in advanced manufacturing, Amaero is committed to innovation and sustainability. Our processes and investments are designed to reduce waste, increase efficiency, and deliver long-lasting components while ensuring domestic manufacturing capacity across all industries:

Sustainable Practices: By optimizing material use and reducing waste, we’re able to minimize our environmental footprint while delivering top-tier components. This commitment to sustainability benefits both our clients and the planet.

Adaptability and Scalability: Our advanced manufacturing capabilities allow us to scale production from prototypes to large volumes, providing flexibility and responsiveness for projects of any size. This adaptability ensures that we can meet both the current and future demands of our clients across multiple industries.

Amaero’s advanced manufacturing solutions combine premium materials, state-of-the-art technology, and industry expertise to deliver unparalleled quality and performance. When it comes to crafting components for high-demand applications, we go beyond traditional manufacturing to provide parts that are built to last, perform, and make an impact.

Explore Amaero’s Advanced Manufacturing solutions to discover how we can support your industry with precision-engineered parts.

PM-HIP is a manufacturing process by which components, in a packed powder condition, are subjected to high pressures and temperatures to fully densify the powders to create solid parts. This process is especially ideal for low volume, high mix demand and is suitable for any size part in any material.

Near-net-shape manufacturing minimizes excess material and reduces the need for machining, saving time and costs while delivering parts with high precision and minimal waste. While Amaero specializes in high-melting-point refractory metals and specialty alloys, including tungsten, molybdenum, and niobium, tailored for industries like Defense, Aerospace, and Energy, our PM-HIP business can produce components utilizing any material.

HIP is used to fully consolidate the metal powder, creating a fully dense part with enhanced material integrity, free of internal defects and porosity, creating durable, defect-free parts suited for high-stress applications in defense, aerospace, and energy industries.

Our solutions are ideal for industries with high-performance requirements, such as Aerospace, Defense, Energy, Heavy Manufacturing, Oil & Gas and Medical where reliability and durability are essential.

Refractory-based alloys are materials that withstand extreme heat and pressure. They offer exceptional thermal stability, making them perfect for mission-critical applications in challenging environments.

We use efficient near-net-shape processes that reduce waste and optimize material usage, aligning with sustainable manufacturing practices and minimizing our environmental footprint and our PM-HIP business allows for the creation of Near-Net Shape (NNS) parts, which dramatically reduces machining steps and scrap, which maximizes the use of mined materials, and reduces energy consumption.

Our advanced numerical modeling and PM-HIP technology ensure precision and consistency, enabling us to meet exacting specifications and exceed industry standards in every component produced.

Yes, our advanced manufacturing capabilities allow for scalable production, from prototype development to high-volume production, adapting to both current and future project demands.

Powder metallurgy involves creating components from powdered metals, which are shaped and densified using HIP technology. This process allows for precise, high-integrity parts that are durable and cost-effective.

We work closely with our clients to understand their needs and problems. We formulate a solution that combines our metallurgical expertise, advanced modeling and manufacturing to deliver a complete tailored solution meeting or exceeding our client's requirements.

With expertise in near-net-shape solutions, HIP technology, and sustainable practices, Amaero delivers high-quality, reliable components designed for high-demand applications across various industries.